Trackwork fine tuning: adding both visual and operational details to N scale code 55 tracks.

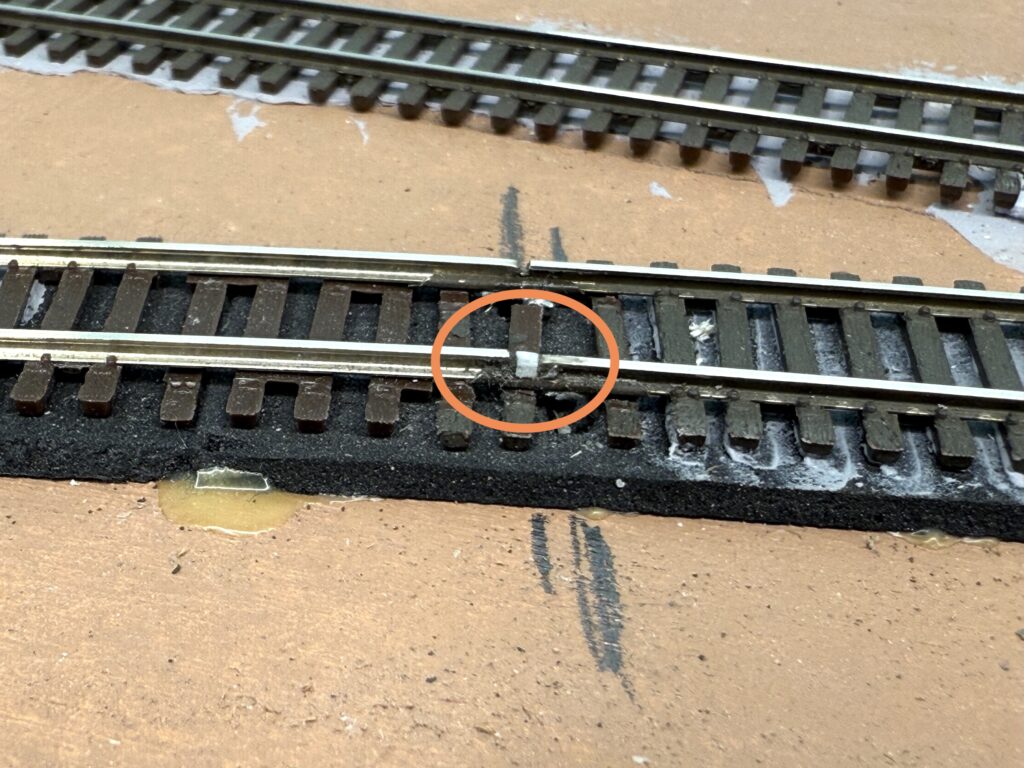

Trackwork fine tuning is crucial for reliable operations. This is especially true in N scale. I added small pieces of styrene to fill gaps at rail joints, helping wheels roll smoothly. The styrene is fixed in place with CA glue, then carefully carved to shape with a sharp hobby knife.

I also replaced the ties I had removed when soldering feeders to the underside of the rails.

In the photo, you can see sections where ties were temporarily removed for easier soldering.

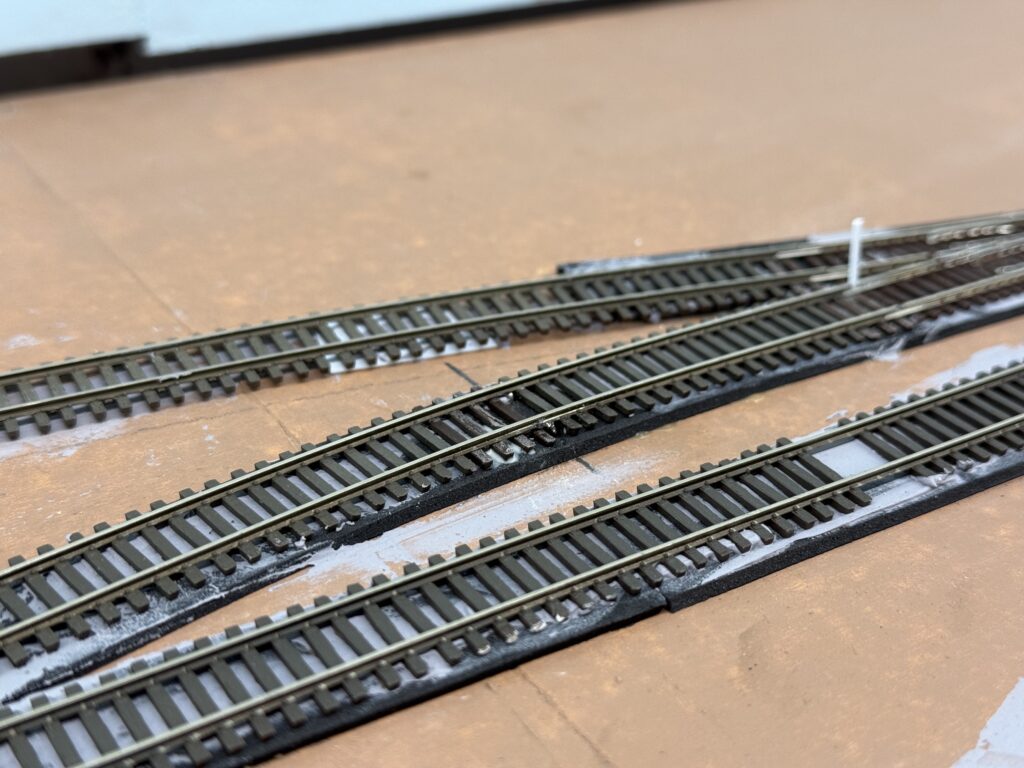

First, I sanded the ties to remove the molded spike details. I laid a sheet of sandpaper on a flat surface and rubbed the ties across it.

Once the spikes were gone, I test-fitted the ties under the rails.

Then I applied a few drops of Titebond glue and slid the ties into place, adjusting the position as needed.

Once painted and ballasted, these small fixes will be barely noticeable.

These small improvements may seem minor, but they make a big difference in how smooth trains run.

On an N scale switching layout, reliable operations depend on well-prepared trackwork and solid electrical connections.

Nothing ruins the flow of a session like derailments or stalling at a poorly aligned joint. Paying attention to these details brings your layout closer to realistic railroad performance.

Clean solder joints and neatly replaced ties also enhance the visual appeal of your track. Each detail you refine adds to the overall reliability and realism of your scene.

Good trackwork is the backbone of stress-free operations. Investing time early pays off later when the layout runs smoothly without surprises. For N scale, especially, precision matters – both for looks and reliable running.